Dust… Keep as much dust out as possible. Any holes I end up drilling I will be filling the old holes with sugru to keep dust out.

This stuff spins, so it creates air streams, but holes are mostly not drilled as not many will change and rigidity too many holes are never OK

I am not sure if @Kug3lis is including any gaskets there. But I planned on visiting my local Grainger to grab a seal like what was provided on my NoWind DD for Trampas, so that I can add lubrication without contamination

Gasket o-ring in black also called slip ring gaskets… just a thought…

I am running my gears raw (dry) no wear after 1k mi  So I don’t know you can if you want but I just see wasted effort

So I don’t know you can if you want but I just see wasted effort  Maybe with lubrication it would be even silenter

Maybe with lubrication it would be even silenter  One of reason why you don’t need lube is POM self lubrication

One of reason why you don’t need lube is POM self lubrication

I think the problem is that you can’t go with another angle for Caliber 2 because then the motor will touch the trucks hanger.

Oh yeah, POM is great for this  it’s one of the best materials to use for gears. I just figured I have the option to get some slip ring gaskets, so probably will for a complete seal, and to aid in silence.

it’s one of the best materials to use for gears. I just figured I have the option to get some slip ring gaskets, so probably will for a complete seal, and to aid in silence.

Those are not for calibers  TB218

TB218

Still same issue.

This is very close to the gound so that you will hit stuff with the motors first. So a steeper angle would be nice so that the motors are closer to the board.

But that doesn’t seem to be possible because the hanger is in the way.

Or am i missing something?

Randal baseplates & two choices of caliber baseplates & Angled wedges,you can create an angle as desired.

Also some crazy people like @Sender & myself plan to try skate trucks on a tipped deck (La Croix). I for one welcome the adjustability.

Just seen your edit and you have a point.The extra holes allow you to mount the drive outboard - to the other side…or up in the sky, or bouncing off the tarmac…options

As @banjaxxed said there are multiple ways to mount the drive so you have many combinations. Also the smaller gear ratio the further is motor from hanger

I’m mounting on the Evo with -15 in the rear so likely will be going down instead of up.

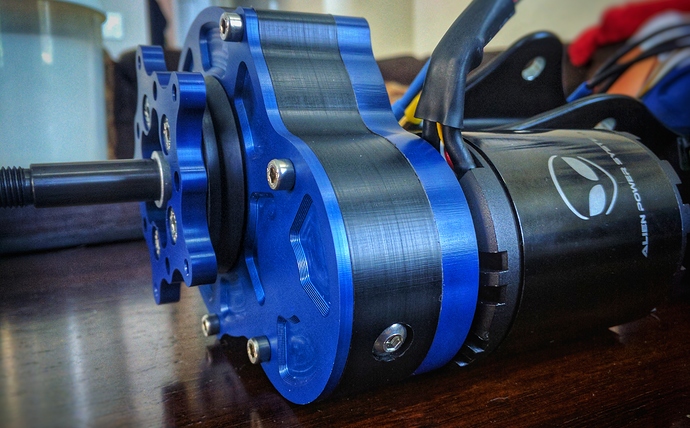

This looks super awesome dude. Super solid! Do you have any video’s of the drive in action? I’m curious how they sound compared to my trampa direct drive (from Jenso without helicals).

If Carvon fails to deliver my speeddrive the upcoming month I’m really interested in this as an alternative as well. Got an Evo deck so I’ll be watching your experimentation.

The half predrilled holes look like 15 degree steps.

But that doesn’t look like there is space for 15 degrees.

I just got message that there will be teflon gasket in the final version as they didn’t delivered them on time

I do not yet, waiting on the remaining parts for the “Day Walker” but soon. Spinning it by hand is quieter then spinning my belt drives by hand, and I haven’t even added lube yet.

Oh this will be more than an experiment I feel. And I’m pretty sure @Kug3lis has some fun up his sleeves for the future. In a week or two when it arrives, the likelihood I will build anymore personal builds for myself with belts, is going to come to a halting 0% belts in my household.

See! Perfect. That’s great for everyone than. Sealed :), if mine didn’t have it no worries I have the Grainger by my house I plan on getting them from. If you don’t mind PMing me the details about the sized used I would greatly appreciate it

This is 6384 motor so its bit too long

I see you guys pressed she shaft out the back. It actually might fit dual 6384 if the shaft was cut on the front side of the motor.

For everyone’s sake. I will bolt up some 6384s to the drive just to confirm without the shaft pressed as if I was going to cut it instead of press it…