Awesome, I may need to get them for my current build I’ll find out soon

Thanks @Andy87 and @xilw3r for the fuse info!!

@DK-Odense oh man that’s terrible and has me severely worried. How long ago was that? Did you ever find the cause? Looks like the bell bowed at at its resonant frequency which makes sense with the loss of power due to the magnets being pulled away not making great contact.

@AlienPowerSystem do you guys know what caused this or a solution?

@Nowind hey brother will that drive system work with the leopards? Looks like I may have to switch if these Alien motors don’t work right.

About 3 months ago.

We tried with different vescs and different setup/motor detection parameters. We ended up concluding that this motor just did’nt fitted for this type of task. Bruno from aps was super cool about it, and just said that we could send it back and we figure something out.

I have two 80100 running without probs, so it is not a “80 mm” problem.

Nope, Alien APS 80mm has different Bolting Circle then LEOPARD

I used 8085 and 80100 APS Motors without any problems. Good Motors , Fair Prices, nothing to complain

Ok cool I’ll switch over to one of them if these don’t work out! Thanks brother!

I will try this one out next if this is a problem for me. Thank you!

Started working on the vesc holder. Will trim off the tail when I figure out exactly where I want it to sit.

Hey mate ! Massive beast coming here  Just to report (what I could, and if it could help a bit), the noize doesn’t sound that bad on some video here … I mean its a “standard” from APS motor no ?

The RSPEC got a special noize too at some rpm ?

I admit that here it’s worse … your problem 3 vid is a bit scary.

Just to report (what I could, and if it could help a bit), the noize doesn’t sound that bad on some video here … I mean its a “standard” from APS motor no ?

The RSPEC got a special noize too at some rpm ?

I admit that here it’s worse … your problem 3 vid is a bit scary.

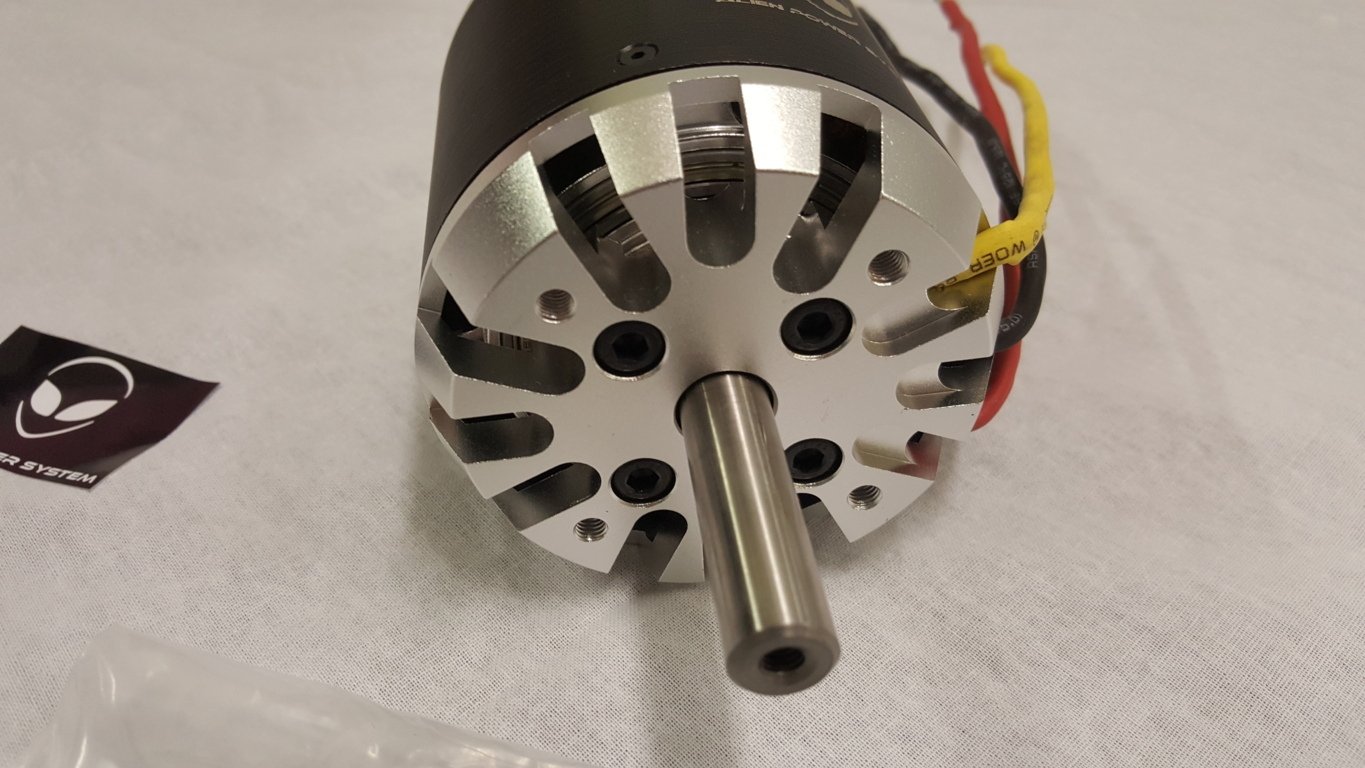

Did you think guys this could come from the under-sizing bearing and all inside stator-rotor configuration make like 63xx motor? Opposite to the 8085/100 who got huge bearing inside and weight a lot more (I have dissected mine for a project not used yet, that what scared me a bit since this. And got an 8085 not set yet), it looks getting bigger/better quality and strongest conception … (IMO at 1st looking in hand). As bearing and also 10mm shaft against 12… for example. Did the high kV could be an issue on a big motor like this ?.. refound some old vid of my APS 63xx, sound a little bit like you :

Cool setup anyway !  I will follow this crazy big toy setup !!

I will follow this crazy big toy setup !!

Maybe. My bearings on 8072 was not smooth at all

I was more thinking about the size, and maybe the design and implementation of them :

… just look stronger on the 8085/80100 one !

… just look stronger on the 8085/80100 one !

for the stator copper/wires, should we resin it ?

https://discourse-cdn-sjc1.com/business6/uploads/openrov/_optimized/5bc/d06/d93c2e0a29_543x480.jpg

https://discourse-cdn-sjc1.com/business6/uploads/openrov/3254/92be0712c6b36826.jpg

I would like to upgrade them before to be disappointed  ?!?

?!?

I think I am done with the vesc holder for now. Got the spot welder in today so about to start putting the battery pack together! Pray for me lol

Busy busy

Have dual layer nickel strip 8mm .15 pure. Then adding these copper wires in series. Then it’ll be silicone tapes and heat shrinked

Waiting for bms to come in. Going to hook up vesc’s tomorrow temporarily to set them up with the motors so I’ll be ready for @Nowind direct drives when they get here!!

12s8p? Nice! I am no expert on building batteries having only built one myself so far but it seems to me that by using only 2 layers of 8mm x .15 nickel you are limited to only about 40 amps max capacity in your series connections which is not nearly enough for what those motors will draw or what that pack could produce. But maybe you know something I don’t?..

I don’t know a lot about batteries myself. From what I understand from reading replies from some battery guys in here is that the parallel connections don’t have to be so robust. The series connections is where it’s needed most. We’ll see though. If things get hotter than I’d like or the motors don’t het the acceleration desired I’ll try adding some copper wire to the parallel connections to see if it makes a difference

For i build like that, with those big motors. I would go with lipo instead.

I guess you don’t understand what I am saying. Your parallel connections would be more than adequate if it was only handling parallel current but because you don’t have direct cell to cell series connections it must also handle series current and is therefore insufficient.

Oh I see you think the distance bereeen the series connections are too far apart and probably not enough causing the voltage to travel down to each connection before crossing.