Just wrapped this up…literally… this is probably my 5th build and probably my best one yet. I def have all the tools and materials and feeling like enough of the experience to possibly offer entry level services to people if one happened to be interested but more interested in what others think of my handy work this time.

I had a 6p brick of 30q cells from my e-bike that were barely used…so I ripped it down and de-burred everything. This time I used .15 x 10mm nickel and used 10-12awg wire across series connects for max ampacity.

After using strip this build I feel like nickel belt is quicker and if using silicone wire across series connects then whats the point of doubling up layers or using wider/thicker nickel?? Ill keep that open for discussion =)

i like to start with my longer strips first…

then do the smaller strips

then add the wire across series connects

tack on tabs for balance wires…

Fish paper under the balance leads

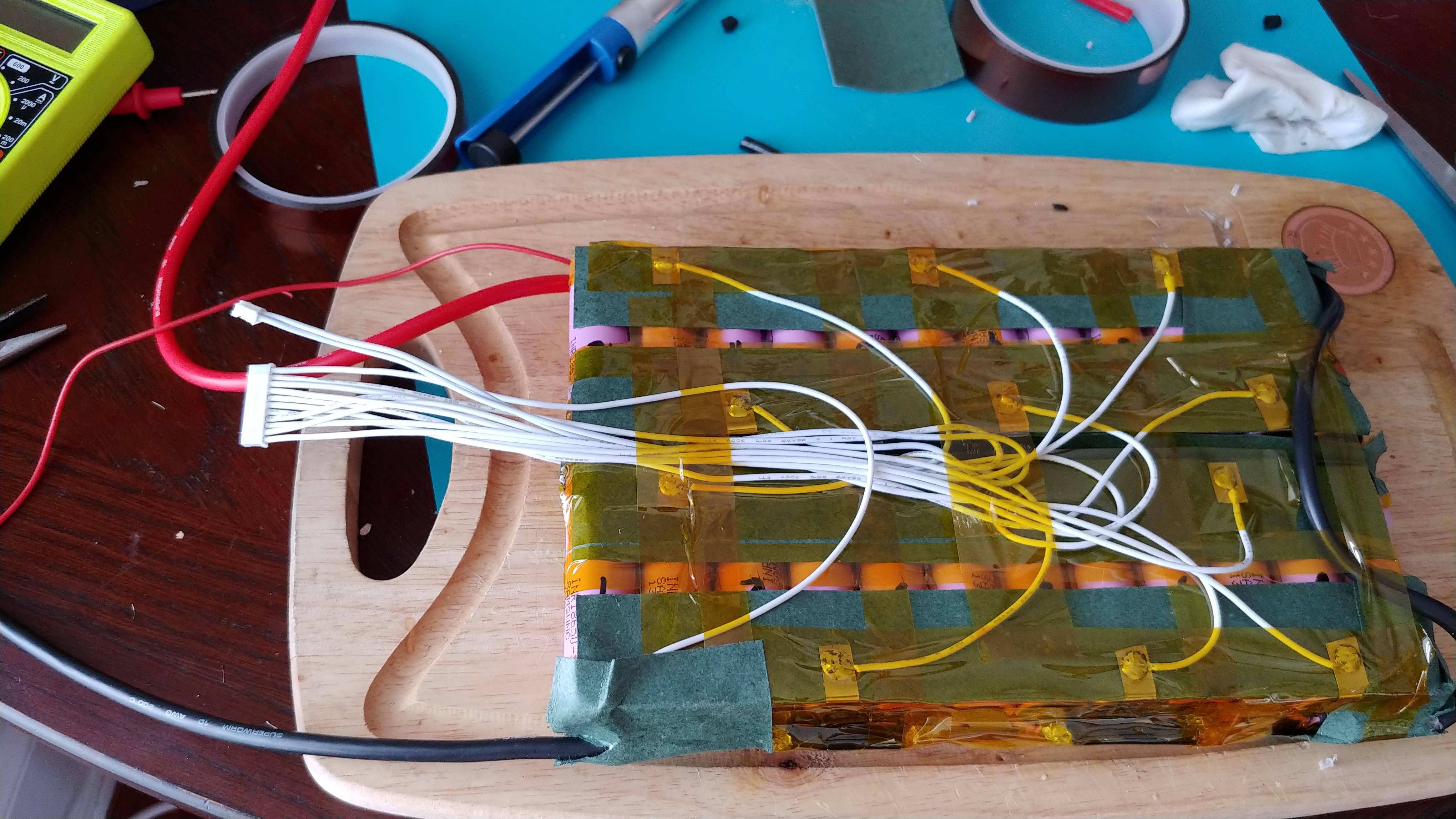

some kapton across the cell tops/bottoms

added my series connect from block 1 to block 2…

cover the inner ends with more fish paper and contouring around the silicone wires for mild offset when sandwiching the 2 together…

tape the 2 together and make sure things are lining up properly…

add balance wires…cover with kapton… added main negative wire…

added main positive wire…

couple strips of shrink wrap length wise to snug things up…

sexy black the rest of it…

added bms wires… charging wires not pictured suring assembly pics

ready to rock once I get an e switch and time to feel da boost.

thx!