This is an eboard. I built it myself with all enertion parts. Does it look like the raptor mono?

Photos messed up. Don’t know why…

I imagine it does…if you’re goofy footed. Done any range testing? I have the dual and battery shows about 25% after 10 miles of moderate riding.

is this a rhetorical question?

You used all the same parts, so yes it looks like a raptor mono ![]()

i would not have the motor wires like that though! you will damage the motor.

How should I put the wires?

This thread is hilarious. I came in here expecting to see a chinese knockoff of a raptor.

Are you asking if you built your raptor mono correctly?

Onloop is right of course, you’re going to need to rotate that motor 90 degrees to have those wires pointed back and down so that they fold under the truck correctly and flow back towards the box against the deck.

don’t forget the black paperclip.

that’s pretty typical of the space cell even in other boards. I get the same results in my Scarlet builds.

Could you explain differently. I’m not sure I know what you mean.

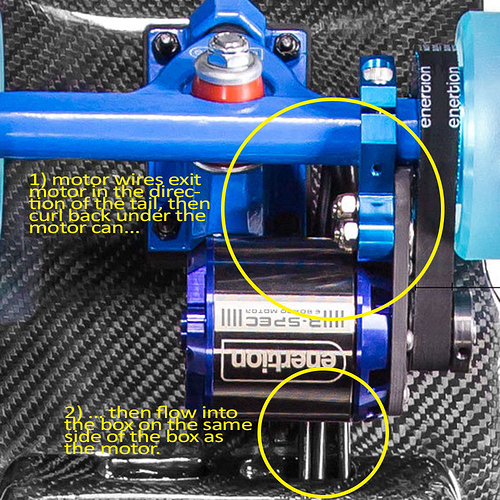

i have a raptor at home waiting on some parts to repair it. I’ll take a pic when i get home of it, but in the mean time, here’s my rat board as an example:

just ignore where the motor wires are plugged in for a minute. That’s a different conversation altogether.

But look at which way the motor is pointing its wires. They come out of the motor and point toward the back of the board. That’s which way yours should be pointing. Then they curve back under the motor and head back toward the box while the natural springyness of the silicone wire keeps them against the bottom of the deck as they enter the box.

And what does that do exactly? Changing the wires.

And what black paperclip?

@eskateking Shit i forgot to snap that pic last night. Sorry man, i’ll try to remember to get that as soon as i get home. in the mean time, here’s something i that might help based on the product photography on enertion’s site:

Pointing the wires toward the back of the deck then letting them curl under the motor can and flow back into the box keeps them from hanging low and potentially snagging things like sticks or rocks or cracks or whatever, which will eventually lead to motor damage as the wires get yanked out of the windings. On my builds, i take this one step further and put the motor plugs immediately next to the trucks in order to keep all of the wires protected by the motor cans and truck hanger, and it also removes every last bit of unnecessary strain from the wires.

Is this the generally preferred wire routing configuration if you’re using a hobby motor (SK3, Tacon) that has stiffer wires? I have mine set up like the OP, and didn’t realize I may have it wrong until now.

It’s just slack they are referring to…they use the slack and the truck to protect the wires from any snags so the bullet connectors or worse the wiring gets pulled out…

I use wire sleeves to protect the wire and use an “S” formation to give me slack…so basically I have longer wire … But mine are totally covered in the sleeve…

I like the wire … Reminds me of an Aorta…otherwise that’s the only wire you see … Unless you start putting lights

Different people do different things. As long as they aren’t hanging down, rubbing on the motor can, or in a state of constant tension, whatever you want to come up with is probably just fine.

Thanks guys. This helped a lot.