Finished set:

The upper side is a bit ugly but you can file it easily for a nicer shape. The wobble is totally gone as far as i can tell already

Finished set:

The upper side is a bit ugly but you can file it easily for a nicer shape. The wobble is totally gone as far as i can tell already

Man this great

Love this work you been doing.

Thanks for sharing

Those are awesome.

Thanks for the nice feedback  I already told my girl about this since she was always like: Why don’t you just buy this? She couldn’t believe that you can’t buy these

I already told my girl about this since she was always like: Why don’t you just buy this? She couldn’t believe that you can’t buy these

That’s freakin awesome

We do sell smaller quart kits but shipping to Germany is expensive. Just for reference, Hummie used F-190 and M-3190 for wheels. F is faster gel time, M is a Medium gel time. If you aren’t in a hurry, M-3190 is safer for newbies. With any urethane, it’s best to give them some heat after demolding for the best durability and abrasion resistance. He used a 90A because after they heat up on hub motors they soften up. But 80A is fine too, especially if you are making thicker wheels. https://bjbenterprises.com/index.php/polyurethanes/castable/flexible/fast-demold/f-190-a-b-3110/ https://bjbenterprises.com/index.php/m-3190-a-b/ https://bjbenterprises.com/index.php/m-3180-rev-1-a-b/

Yup, will work perfect for you.

This is not the right material. See post below…

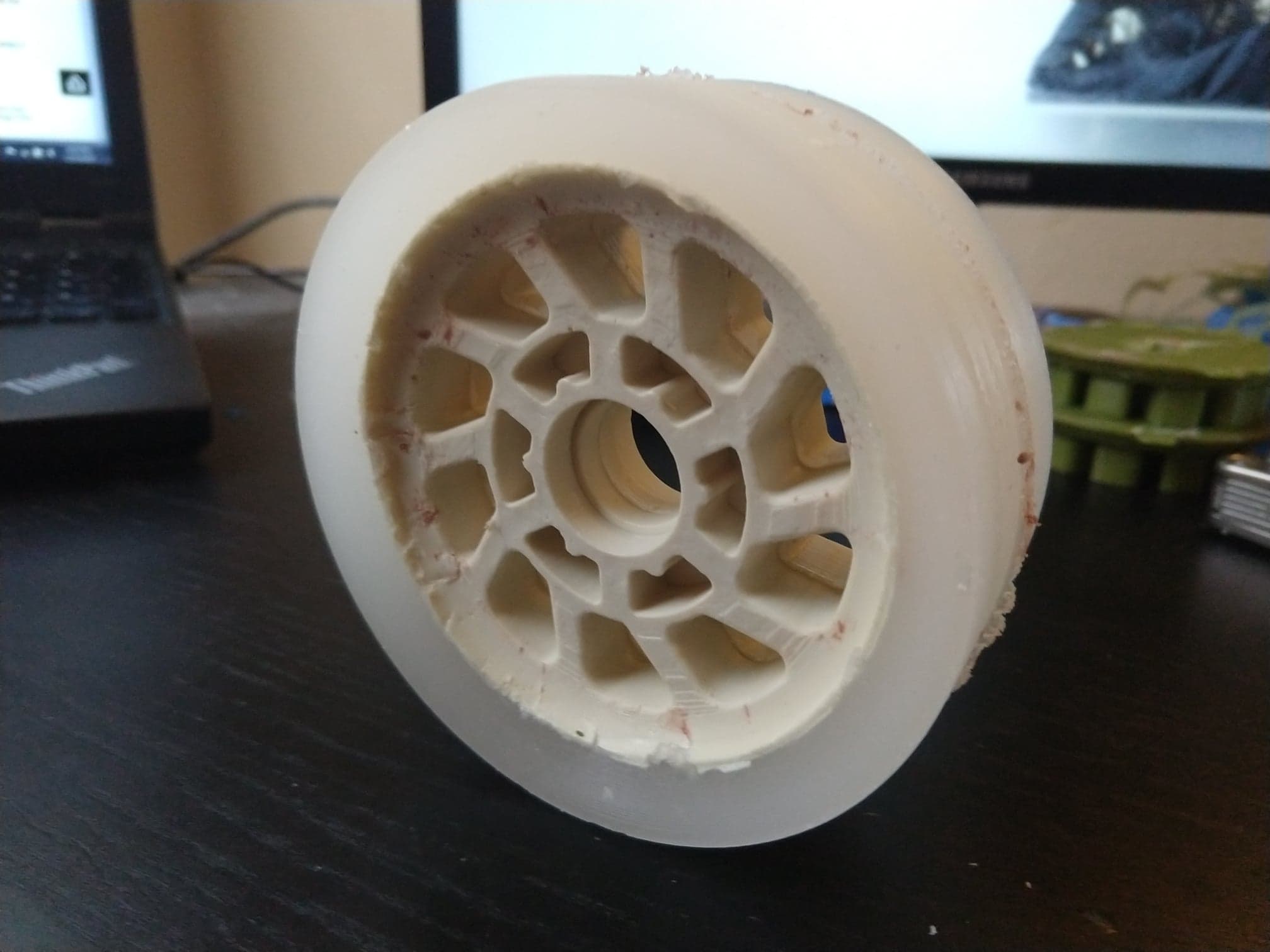

Silicone mold taken off a high resolution 3D print, then 2-part 90A urethane cast into mold. https://bjbenterprises.com/index.php/f-190-a-b/

Wow, thanks for the insight

It warms my coils when vendors get involved in the fine details

Those look so awesome

We’re also casting our own eskate wheels and looking for feedback. 70D core that then has a 80A tread cast over it. Having some trouble releasing hard core from hard tooling, 3D printed. Tread tooling is also 3D printed but releases easier from flexible material it seems. Next iteration is adding draft to the core tooling to improve this. Compatible with both ABEC and Kegel drive patterns.

@visnu777 But the mold @Pylonflyer made will be hard to get the tire out unless maybe with an air compressor. I think he said next time he’d do it with the center and outside on different halves of the mold to get it out easier. I did molds that way and would add a lot of mold release so the tire would get stuck only to the inner part. I did molds for the same tire also with Half the mold center n outside on both halves of the mold. So split in middle, leaves a bit of flashing in center but comes off easily and if u do a good mold even better. Even then it can be hard to get out.

I made my molds by sitting the print on a one inch brick in the big cylinder with sealed bottom. (Oatmeal tube n tape). Melted coconut oil and filling up to half way up the tire, it solidifies, then pour the first mold half on top (the bottom of the mold). Melt the oil off and then pour the second half w some wax sticks for pour n airhole. Make the holes big to get the resin in quickly. I used a small hand vacuum to suck the resin in even with big holes. and make a reservoir or even a sheet of acrylic taped into a cone like pylonflyer did. Better if u have an attached reservoir if u suck it in. and there’s silicone glue and u could build a reservoir , or u could pour a reservoir on top of the mold directly with wax walls.

Yup, I would change my mold shown above to have the inner part (where you see the splines) attached to the lid so it pulls out first and then the wheel would slide out much easier with a blast of compressed air. The wheels still came out reasonably well but it took a little extra time with all the extra surface area on the inside and outside walls. Since there are no draft angles on a wheel, you just try and reduce surface area contact. We did a video on how to approach 3D Printed molds recently. I would love to see what your molds turned out like, too!

Having said all that, silicone molds are still my favorite option for making less than 20-30 parts IMHO. Just use stiffer silicone and take a little extra time setting it up so it doesn’t fight you later when you’re demolding parts.

Did it again, this time I used meepo and Co replaceable sleeves, worked like a charm

The original sleeves are 90mm, now they are 110  like the MBS AT wheels I used for the cast

like the MBS AT wheels I used for the cast  edit: they are 100mm actually, so are mine

edit: they are 100mm actually, so are mine

Finished and back on track

it looks really bad ass