Yep but I reinforced it with fiber tape

^ this adds reinforcements

Yep but I reinforced it with fiber tape

^ this adds reinforcements

how? only if you place them in a spacer while silicone them together.

if you just put press them together and than put the silicone on it it will not come inbetween the cells, so no gap there.

I welded the cells then applied silicon

It I take the silicon off I can see a gap

right, you! other people might make that different.

Here is an example of my first battery build. I’ve already wrapped the whole enchilada in shrink tube, but figured that showing you a current picture would defeat the purpose of displaying the wiring layout. There is now a thick piece of foam in between the two battery banks.

This is the inside of a Meepo 8Ah battery with Sanyo 20700 cells.

This is an Enertion battery cut open.

That’s very tidy, nice!

I don´t like that at all

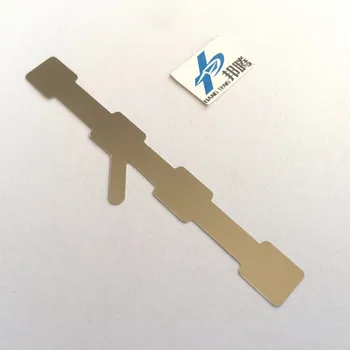

There’s fishpaper underneath and plastic covers over it stopping whatever object punching those edges down. Although it still would be a nice touch to use proper custom 4p tabs.

one guy here did that as well… but non the less his board catched fire in the first week and this might have been the cause of it.

This one here is no folded desing, so it´s maybe less likely, but non the less, it´s not a big problem to cut corners or place the nickel right to totally eliminate a changes of short the cell out in this place.

Probably because there is no isolation between the P groups.

no, because the corner bend around. due to vibration and the folded design the corner was pushed through the fishpaper over time and shorted the cell.

Oh nice, never seen anything like that. Where are those from?

Google image search

Yes I was surprised to see the squared edges on the positive terminals as @Andy87 said that could potentially pierce through the fish paper. I’ve measured the thickness of the Nickel at 0.15mm. There is 2 layers so that could be a lot of amps going through that to get to the connecting silicon wire. I think it is two layer of Nickel between the P groups too. I’ll check when I get home next week. I’ll be pulling it apart some time soon so I’ll be able to seen how strong the welds are too. I’ll test a couple of cells too to see how they perform. The guy who gave the battery to me wants the configuration changed. The balance wires are laid on top of double sided sticky tape, good way to keep the wires in place while wiring up. Not very thick tape though. The plastic dividers and caps make it a very ridged battery pack, not suitable for boards with flex but not a problem for the Raptor which it was designed for.