Guys I need your help!

I bought Ronins cast version. Today was the first day that I ride using them and I have mixed feelings.

They are smooooooth and feels very good but a bit unstable. I have stock bushings those red ones that are I believe 90A. My weight is 76kg.

The big factor might be that I’m not a skateboarder just a simple beginner but it’s hard for me to imagine to go on them even 20km/h. There are some people here that use them so please help me and tell what to do.

I’m also in process of designing CNC milled hanger for them so hope this thread could be filled with all the info about these great trucks

Have you tried them on a commercial board? The kegels and tarmac are not the problem

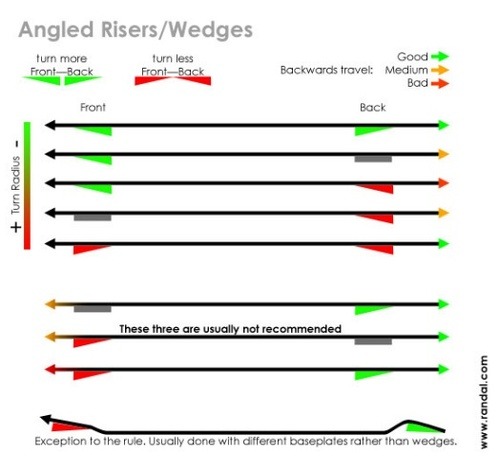

are these angled risers between truck and board? the angle looks “very turny”, combined with that short wheelbase it might be a little extreme. ronins are usually way more precise and stable than other trucks around zero lean and quite turny when you lean in a lot!

@banjaxxed no I don’t have one do you think it might be deck related thing?

@whitepony look at the picture. My deck is not finished yet so I tried to mount them as straight as I can. Do you also suspect that it might be because of deck? I saw that you are using white bushings. Are those hardest Ronins with lower rebound? Theoretically for my weight those red one should be ok?

I use some 6 deg angled risers from Bolzen witch happen to be shock absorbing too. Compensate the shape of your integrated deck with the risers.

Remember that on a directional setup you want a smaller angle on the rear:

For ex. 50 deg front + 43 deg rear

Will that CNC hanger have some rake?

How long is your wheel base?

Get a set of iced tea bushings to start and put them board side and see how they feel then… (they are the next duro up)

Or go post in @Alphamail riptide bushing thread and ask for his help with his bushings.

for that short wheelbase I would probably de-wedge the trucks a little (make them less turny):

Im using riptide 93A krank tall barrel board and 87A crank roadside - its harder than original to cater for the higher average speed when cruising with an electric motor.

I remember I didnt like the ronins on my jet spud build, cause it was too turny due to the wheelbase. went with 44° calibers instead there. on my vanguard the ronins are just miles above anything I ever tried, but thats a massive wheelbase of 90cm!!

Yeah tuning bushings is a process…

Taking some angle out of the rear truck will help, but at 42.5 degrees I would leave the front alone.

Running the rear bushings firmer will help too, although I always change things progressively. Even just a iced tea board side in the rear might will help?

There rarely is an actual need to start wedging or changing bushings on the cast ronins or even calibers.

Ive taken the cast ronins up to 90kmph with the stock bushings, they are insanely stable trucks due to the queenpin.

Try tightening them up a bit. It may be the wheelbase of your deck thats making them feel unstable. Maybe use cupped washers too.

you still need to dial in the amount of turn for your lean - i ran ronins on the 29“ jet spud and they turned so hard that you could use only a fraction of your full lean at low speeds. in that case de-wedging is the right thing to do since bushings only restrict your lean and dont really solve the problem of your wheelbase! i think thats what @LukePL actually means when he says „unstable“, because ronins really cant be unstable, but the board can feel twitchy and overly agile/nervous if it reacts strongly to every tiny bit of lean! youd have the problem with any truck I think!

ronins come with cupped washers already and careful with overtighten bushings - nothing can be solved with that!

It would give you something known to help come to a conclusion. The unknown factors are that board and well yourself

Thanks so much for all your advice! Things that I’ll try first is to de-wedge rear truck like @whitepony said. You are totally right that I meant nervous behavior. @banjaxxed it’s true also. I can’t skateboard yet and the deck… I think that it’s shape make it transfer every little move to trucks. The curve of the sides is too much. A lot of tuning ahead of me but that the fun right

Planned to make straight copy just wider. Now I might experiment with that. Any suggestions?

Depends on how wide you wanna go but I would try to accommodate 5-6 mm positive rake which apparently makes the truck a bit more lively. The CNC Ronins have about 5 mm rake!

Luke have a plan and understand the changes you are making before you try them.

More rake will make what you have now more twitchy/lively.

This is my winter ride, it has a 25 degree rear plate, cupped washers top and bottom, Horchatta bushing board side and a iced tea road side. Currently a 154mm hangar with 2.5mm of rake but I might go back to 164mm.

My front truck is different in almost every way. more rake more base plate angle…

This gives me turn but also keeps the rear stable.

Have a plan before you start of what you want.

The issue here is that you can’t make the ideal setup for low $. Hanger front and rear need to be almost identical for cost reasons (milling is going to be expensive). Rake or no rake, a long hanger on the order of 10 inch won’t feel as agile as a 160 mm hanger, so wat to dooo? I agree with having a split setup, something like 50 degrees front, 45 or lower in the back. Stiffer bushings on the rear than on the front. And that alone is better than say 75% of the Alibaba trucks including Torqueboards 218 mm!

@anon42702729 as you can read I don’t want those trucks to be more lively at least not with this deck and my skill level

@Cobber a good plan is the way to go but it’s hard to plan something when you don’t have the knowledge and that is why i’m asking you guys. Your setup is highly tuned in every detail and you probably have tried a bunch of them before that. As I understand a graphic representation what you have is 3rd from the top in the Angled risers/weges graphic that @whitepony posted? So now I would need a simple advice what to do and try next.

Maybe @Alphamail can add some advice here also?

Is it possible to make this hangar like that? To flip it and change characteristic?

To flip it and change characteristic?

With cast Ronin trucks, dewedging the rear can go s long ways in making them bore stable. Leave the front as it is and dewedge the rear 2.5 to 5 degrees. I find the stock bushings very bouncy so I normally run KranK TallBarrels in 90a for my 90 KG / 198 LBS. If I dewedge the rear I run cupped washers in back, top and flats in the fron