I know right. I like the look of it, it has a kicktail which is helpful for sharp turn. Nice w concave pretty stiff. yeah I think i will fit too. I’m waiting for my parts and it is killing me awweee.

I really admire chaka’s and your effort to sink electronics completely into the board and I dont think there is a copyright on “sinking in electronics into your board” ![]() . the thing i really dont like about these kind of decks is: they always look like tanks cause they need to have at least 2cm height to accomodate 18650 cells.

aesthetically its much more pleasing to MY eyes at least with a slim board edge and a partially sunk in enclosure, which you barely notice from typical viewing angles (unless you are VERY short

. the thing i really dont like about these kind of decks is: they always look like tanks cause they need to have at least 2cm height to accomodate 18650 cells.

aesthetically its much more pleasing to MY eyes at least with a slim board edge and a partially sunk in enclosure, which you barely notice from typical viewing angles (unless you are VERY short ![]() ).

if I would sink in my electronics into a board, I would probably go with flat lipo pouches to get rid of the tank looks.

).

if I would sink in my electronics into a board, I would probably go with flat lipo pouches to get rid of the tank looks.

or maybe center the cells and slim down the edges to normal board levels, so it looks just like strong concave from the usual viewing angles! that would be an elegant way to “hide” the thickness in a visually pleasing way!

Likewise, I think screwing containers to the bottom of a longboard makes them look like a pregnant guppy or a package of lunchables.  Plus, how else are you going to fit 70+ cells on a deck? Personally I find the thickness of my decks to be visually pleasing, thin decks look inadequate to me know.

Plus, how else are you going to fit 70+ cells on a deck? Personally I find the thickness of my decks to be visually pleasing, thin decks look inadequate to me know.  I can feel your frustration though, it is not easy to make decks in this fashion. You may think routing out the bottom of the deck and bolting a tray is a good idea but you will probably end up with cracking and eventual failure if you ride aggressively. Boards should have some backbone.

I can feel your frustration though, it is not easy to make decks in this fashion. You may think routing out the bottom of the deck and bolting a tray is a good idea but you will probably end up with cracking and eventual failure if you ride aggressively. Boards should have some backbone.

I also want to add that I in no way think I should be the only one making hollow core composite eboards. The more people making them the better!

We now have another term for the eboarding lexicon, the lunchable!

you know, I decided against composite materials. I’m going all all wood. I had a layer offiberglass on the bottom that I ripped off yesterday as It didn’t look the best (never really dried, even after a week in the sun) and it doesn’t need it. My deck is strong enough as it is right now, but theres screw holes visble from the bottom, some I’m going to do 2 more layers on the bottom to cover the holes and give just a bit of extra strength. So far with the lid, I’m at 20 layers, might end up at 22 total (16 layers is 1 inch.

I personally think the enclosures on the bottom are ugly. I’d rather have a thicker deck with all the componets inside rather than an enclosure bulding out.)

Nice one. I’ll keep an eye out for whoever posts “The Lunchable” build.

Love @Chaka’s hollow core setup, but it wasn’t the first as i recall.

I have an Omen Chief i’m setting up similar to rs4race who did his in Aug 2014. Omen had a few extra double thick decks and i’ve routered out a huge chunk to house electronics. Here’s his original thread - pretty impressive given 2 years ago!

I started working on this project a year ago! Holy crap time flies… and i’m obviously slow (in more ways than one before the peanut gallery comments.). Started out like this:

Teaser pic - here’s where i’m at:

Love the enclosed electronics option! One of the things i love about my Marbel - stealth. I also have a new Subsonic foam core to wrap next to recreate my e-GBomb - but with enclosed electronics this time. Ultimately i’ve been practicing lately w/ these so i can do the next e-GBomb proper and get my skills where they need to be to do it justice. On the shelf waiting patiently… I’m slow remember!

So many cool decks - it’s hard to limit to just one build!

I don’t know, does routing out a recess in a solid board count .  I would call that a flush mount system.

I would call that a flush mount system.

The decks I build are completely hollow with a maple/fg skin and weigh about the same as a loaded deck of the same size without batteries or electronics.

I’ll just call it enclosed electronics. They will be under a lid of some sort (gf/cf/kydex etc.) and as flush as possible to fit the size batteries i want for range.

I want mine accessible and swappable for more range by swapping batteries. But KISS - no BMS and basic HK lipos currently. Might eventually join you cool kids w/ BMS and 18650 packs… but will wait till my existing lipos have issues and need to be replaced.

I cnc mill each layer, pressing them 3-4 layers at a time (due to the limits of vacuum pressing).

They are built from raw materials. Chaka’s are also. And it makes for a special board.

heh, not sure why you would think that - unidirectional carbon is so incredibly strong … after riding the heavily routed spud and jumping a few stairs on my first testride I feel that the board is actually stronger than stock now with the 3 carbon layers. we have seen boards that snap after routing on this forum, but to be honest, Im almost certain that the particular picture that I have in mind probably didnt have a good bond between board and carbon, which of course is deadly, since once it delaminates, the whole stability is gone. thats why I prepare the boards wood with very rough P40 grid before I lay carbon!

in the same fashion I could proclaim “these hollow core skeletons of a board, you may think its a good idea but you will probably end up with cracking and eventual failure if you ride agressively. boards should be solid and not hollow!”. ![]()

I didnt have a snapped board yet in a total of probably around 3000km - do you? ![]()

you most likely didnt add enough hardener. its very important to be precise on the mix and then really take your time to stirr it up really well. I always use a stopwatch to make sure that I stirr for at least 2 minutes! ![]()

I feel pretty confident that my modified double thick deck will hold up. I have multiple layers of 12k CF on top, uni CF and angled CF tube w/ 3k on bottom. But i’ll be sure to slowly ride and stress it to check before going full speed!

Haha don’t be so sensitive, Just trying to give you a bit of friendly advice. Carbon fiber is great but you are really not getting any benefit by adding it to an area with neutral flex. You are relying purely on the strength of the two outer stringers.

On a hollow core deck you rely on having a strong composite skin along the entire bottom length of the board. A board built similar to your last build should still have a central stringer to help take the load. Either way preach on brother, peace be with you!

I did exactly what the instructions said. 28 grams of fiberglass resign to 10 drops of hardener. I also stirred for quite some time, at least 2 minutes. Either way, it’s not necessary. hummie and I did some testes doing small jumps in the center of the board, and its as solid as can be. The board I used to mold it is more flexible than my board. And I’m adding 2 more layers on the bottom just to give it even more re-enforcement and hide some screw inserts.

@chaka A good hollow core depends on having a strong few “base” layer(s). In my case, I have 3 solid pieces (face, cross, face), and will add another cross and face to make it 5 layers (while a normal board is 7-11 layers). The spar structure takes a lot of load, as I’m sure you have seen with your board. With only 3 layers of wood on the bottom and no CF or FG, the board barely bends. It’s very stiff, sue to the spars on the side and the middle. In your case, you use a composite of materials, mainly carbon fiber. As long as you create a stong base (with whatever materials you choose), you should be fine.

On a completely different topic, you solve my problem of where to put the vescs by using 3 hollow channels instead of 2. How wide/long is your deck?

Your bottom layer is still regarded as a laminate/composite but you will want something with a bit more tensile strength if you get really thin. 3 layers should be fine, figure a park deck is only 7 layers, only the bottom 3 layers are under any stress.

My boards are usually about 10 inches wide. The central cavity is nice and it allows you to extend your batteries all the way to the wheel cutouts.

Hello! Looking for some Options as far as decks that the enertion space cell enclosure can fit on. Currently have a dusters deck that works fine. Just looking for different styles of decks!

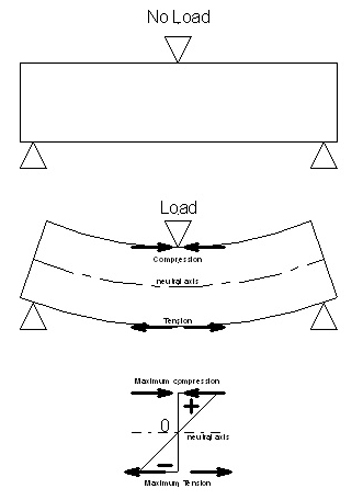

the “neutral area” is still the middle of a boards material, no matter how thin I route it … and the stretching area is always the lower half. that is the reason why thinner boards have to be more flexy when you use a thinner and a thicker board both with the same material: the elongation → tension becomes much higher with increasing thickness, because the material has to extend more. mathematically speaking: in your picture you bend a straight line into a circle segment = increasing its former length when bending on the lower half of the material, compressing and reducing its former length on the upper half of the material. now, the thicker a board is, the larger the outer arc segments becomes when you bend it = the more it stretches.

now, since the board becomes a lot thinner in a few parts due to routing, its up to the tensile strength of a material to make up for the lack of elongation, at least if you want to preserve the flex … and cfk has about 10x the tensile strength of hard wood, so no issues here. but in the end the bond of the carbon to the wood is crucial too because the shear forces connecting the layers really help out on the stiffness and stability! so one should always make sure that the epoxy can really grip into the wood, hence the roughed up surface with P40!

its actually a good moment to talk about “should I add cfk/gfk ontop or on roadside”?

GFK has a very similar compressive and tensile strength, so for gfk it actually doesnt matter if you put it ontop of the board or below.

CFK has a better tensile strength - about 2x as much as compressive strength for the materials Im using, so if you put it ontop of the board, youll only get half of the effect compared to roadside.

but: lets say you have a board of 1cm thickness and you add another 1cm CFK roadside, then the new “neutral area” of chaka is the boards former roadside and you added a lot of cfk close to the “neutral area”. in that case it would be better to add CFK at both sides evenly to get the stiffest result.

in practice that example of course does not really happen - even 2-3 layers of carbon are thinner than a singly ply of wood!

if your resin didnt cure, its because it lacked hardener - no other explanation! “10 drops” is also a really fishy way of measuring (unless you meant 10gr). in such small quantities, its probably better to mix by volume and not by weight. it IS really crucial to be precise and the smaller the quantities get, the bigger your relative error. if in doubt its surely better to use too much than too little hardener - with too much hardener, the physical properties wont be as good, but it will cure at least. with too little hardener, parts of the resin will never cure. ![]()