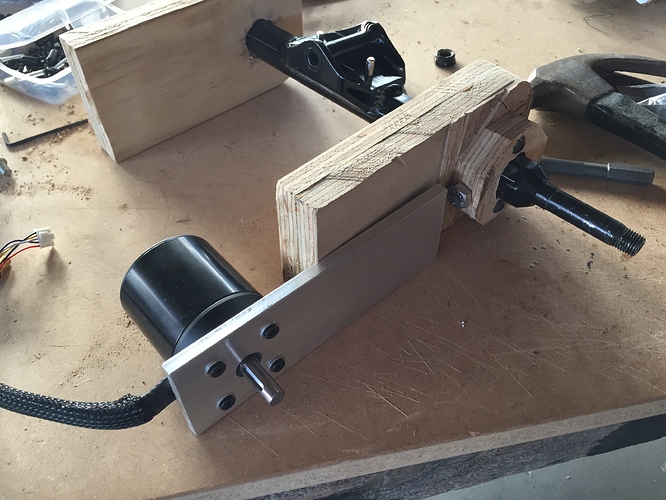

The drive chain is getting close to functional now. Love the Ollin Board Company motors design, lighter and smaller than the emax ones, I’m sure they’ll be much better. My aluminium bar showed up too so I was able to make a much better motor mount. I’ll keep the plywood part though. Had to cut that back a bit to give more space for the wheel pulley.

I apologize if all my replying to my own thread is annoying anyone, it just seems appropriate to keep a kind of public build journal here. Please tell me if you’d rather I keep it down!

So after tonight’s work I have a powertrain, though probably not a usable one.

I have a couple of issues, one is that the tight belt is pulling/twisting everything towards the wheel, which is bending the plywood so the belt wants to slide up towards the wheel. I may have to totally ditch the ply for that reason, which I sort of knew but hoped I could get away with, you do definitely need a rigid motor mount.

The other issue is this:

I hand drilled from the other side to enlarge the pulley bore, and got a horrifically off-center result. It’s unusable in this state, when I twist the motor it oscillates strongly as it pulls uphill and downhill, so that’s two motor pulleys I’ve ruined now.

So I am thinking I’ll move to an aluminium motor pulley, and invest in a drill press. My inability to drill straight holes is causing me a bunch of problems.

I definitely learned my lesson with putting the motor pulley on though. This time I drilled a 1/32 inch hole, which gave me just under 8mm, and it was a nice tight fit, which could be easily pushed down with that pulley removal tool I now possess, no hammering involved.

So now I wait for new pulleys I guess. I assembled it in place just to check the motors weren’t going to get in the way, and it’s looking good.

Feeling way more positive after tonight’s work!

I went and bought myself a drill press today, and it has already transformed my life. Seriously, You need one.

With it I was able to resurrect the motor pulley that was banged on too hard. I had somehow with pure clairvoyance bought 3 pulleys. That one with the diagonal hole is no good but I still have two not totally destroyed pulleys left for my dual motor plan. With the straight drilled pulley and the belt tensioned properly, things were looking pretty good, but I wasn’t happy with the softness of the plywood mount. If I yanked on it, the plywood compressed and everything got loose.

So the new drill was put to work on an aluminium based motor mount. I drilled a bunch of holes in some of that 2 inch by 1/4 inch aluminium bar to try to once again make a hole the size of the MBS Matrix ii Pro truck.

With a file I enlarged that mess slowly, until eventually I got the truck to fit.

It’s going to replace the plywood section on the right:

It’s actually not a bad fit, just a little wobble. But I’ll need to figure out how to secure that properly to the truck. I’m thinking a simple right angle bracket will do the trick, so the next step is probably to find/create one.

I also ordered some new aluminium motor pulleys. Much the same as the plastic ones, but should help if things don’t go well, or I destroy a motor pulley again : http://www.bbman.com/catalog/product/16XL037-6FA4

The RC controller I ordered right at the beginning of all of this is due to finally show up next week, so I’m hoping I can sort out all the issues, and this will all be ready to go by then…

This is looking real good well done

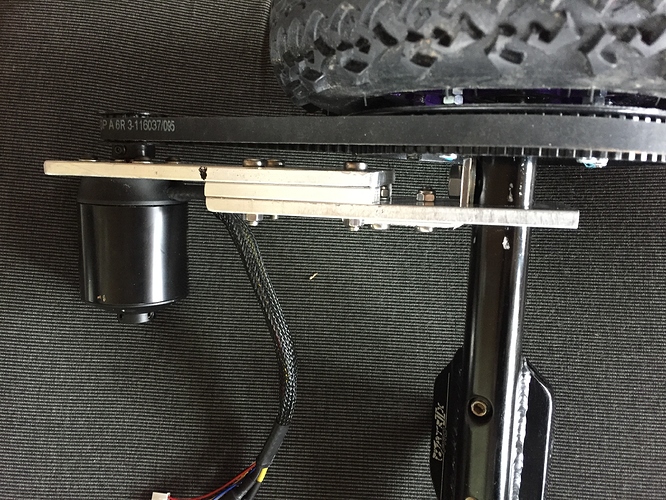

I now have a motor mount that might be good enough to get moving!

I bought a couple of little zinc brackets to attach the mount to the truck. They might not be strong enough, there is a fair bit of flexibility in it all still. With a bit of force I can bend and twist to adjust where the belt sits. That’s kind of good right now, but might not be so good when I’m riding. But the nuts and bolts are all a bit loose. It will help when I tighten and loctite everything.

It’s feeling pretty smooth when I spin the wheel or motor. The belt is sitting a little off the wheel pulley, but there are a few things I could do to fix that if it continues to be a problem. The middle of the 3 aluminium plates is basically acting as a spacer to get the motor closer to the wheel, I could add another. Alternatively I could put the truck mount plate on the other side of the bracket, but there’s a bunch of finicky filing involved in that. Or I could just add a bit more space between the wheel and the wheel pulley.

This is a sort of exploded view of the mount. I had to cut out a space for the truck bracket, decided that was a better option than losing the second bracket screw. Unfortunately it meant the bottom hole has no top edge, but that’s OK, that plate isn’t really structural.

This is all much harder than it should be, mostly because I chose to use 8 inch all-terrain wheels, and the trucks that were designed for them. The MBS trucks are oddly shaped and no one makes/sells motor mounts for them. The bracket is unusually long because the belt is unusually long because the wheel pulley is unusually large, and that’s all to create enough torque with these 8 inch wheels.

Loving the process though, this is the first time I’ve worked with aluminium in this way, I’ve only ever worked with wood and metal like this in a pretty limited way 20 years ago at school, so this is a sweet learning experience.

I shifted the mount to the other side of the bracket, and now it’s lining up perfectly. I had to file out a slot for the bracket, but all up it was a pretty simple fix.

It also feels a bit tighter and more secure. So now I’m happy with this mount, I’ve started work on the other mount to match.

Both mounts are functional now, looking pretty good. I think I can remove that spacer plate, the motors have now ended up a little too close to the wheels.

Full drive train & board assembly done!

It’s all feeling a bit rickety and loose to be honest. I think my choice of MBS trucks was a bad one, given the difficult profile of the trucks. However there are still plenty more things I could do to tighten everything up. For now though I’m done with all this drive train stuff. I’m going to do one last disassemble, liberally apply blue loctite, put it back together and get to work on the electronics.

At this point I also kind of wish I’d gone single motor for my first build. Doubling everything up when this is really just a prototype wasn’t the best idea.

First step into the electronics has revealed that I need some thicker silicone wire. Mini-quadcopters are comparatively low on the amps, so I’m mostly using 16-20AWG there, and that’s all I have on hand. My batteries will provide 240A if you believe the C rating, so it all comes down to the VESCs which should handle 50A-240A and the motors I’m not so sure on. http://www.ollinboardcompany.com/product/om5065-170kv says 2200 watts… that’s roughly 85A at 8S x 2 = 170A max.

Anyway, that means I should have 8 AWG from the battery to be super safe, and in fact the 4S 8000mah batteries ship with that, but from what I’ve seen/read/experienced I’m going for 12AWG from the battery to the ESCs and 16 beyond there. I doubt I can find 12AWG silicone wire within a 4 hour drive, so am now stuck waiting for delivery.

In the mean time I cleaned up my bench, and get to lay everything out and plan ahead. It’'l look something like this, but with lots of bright blue ugly velcro and a tangle of wires:

Battery connections for serial to parallel are done, VESCs powered up and configured for master/slave mode over CANBUS, motors with sensors are connected, detected and setup, and Winning controller is working, and spinning the motors nicely!

The battery->ESC wiring looks like a flux capacitor

All that is left is to stick everything to the board somehow. I’m so eager to get going that it’ll be all velcro and duct tape to start with. I’m so super excited, even just getting the motors spinning finally was an awesome moment.

Hi @dinodave,

Your AT build looks like it is coming along well.

I do have one concern - your motor mounts. Considering they are so long, are you going to put some sort of bracing between them so they don’t flex?

To fix this, I reckon you could get away with a length of all thread bolt between the middle of your mounts to keep them 90 degrees to the rear axle, secured with nuts like shown in the diagram below. Will probably need to locktite the nuts.

I agree with @baxter. Add a long bolt or grid style plate will to hold either side parrellel and also give extra support. Other than that I think your setup is pretty rad!

Thanks, I was concerned about the flex, and was thinking about using some brackets and a plate to connect the two, but a threaded rod is a much better idea. I’ll definitely give that a try!

First ride was a huge success! Was super impressed with how it handles gravel, both up and down fairly steep gradients.

I just had a couple of failures. I had hot glued the canbus connectors in place, but one of them was glued in place disconnected already! So that was a quick fix. Then at the end one of my batteries fell off, so I can say that Velcro alone is not enough to hold your batteries! Will strap em in for next time.

So, really good fun, still lots to learn and tweaks to make, but I’m super stoked.

Looks good! Glad to hear the maiden viyage was fairly successful.

Do you feel that dual motors are necessary on MBS AT?

Definitely on gravel, without the connector initially it was effectively a single motor setup, and one wheel just span in the gravel even with no load.

I went dual for extra torque as well as traction, and it feels like the right choice. We have a steep gravel drive I want to be able to ride up and down.

Glad to hear it’s up and running. How did your drive system perform? Are the mounts sturdy enough? Any skipping belts?

No belt skipping, though everything was pretty low speed. I didn’t see any issues at all really, but yeah, need to head out and find some more space to push the acceleration/braking a bit more. It was able to accelerate me up a fairly steep hill from near stand still though, so that’s not bad!

These trucks feel super firm, making it hard to turn. Not sure if that’s just me expecting to be able to carve it up like a surf board or perhaps something particular to mountainboard trucks. I’ve ordered some of the softer yellow shock blocks to mellow them out a bit, hopefully that helps loosen up the turns.

I guess it’s also possible I need to mount the trucks to the board at more of an angle.

great thread and really appreciate you sharing the thought process as you go. Successes and failures - all good info to learn from.

Keep it up and well done!