I’m thinking 170KV would be better…

6374 would be the typical motor used on a ATB, all depends on if on street only and hills, 160kv would help any initial cogging

nice designs

Ps. Use this https://calc.3dservisas.eu

Yes of curse, just like Alan say, if you could, its better go with 6374, maytech got the 170kv to :

if I have money for my 5065, I will choose the Maytech – 5065 170KV Sensored

Does someone have the side profile dimensions of the MBS Matrix Pro Hub, pleas? It seems a bit narrower than the plastic ones… The pastic ones are curved inwards and it seems the Pro hubs are flat…

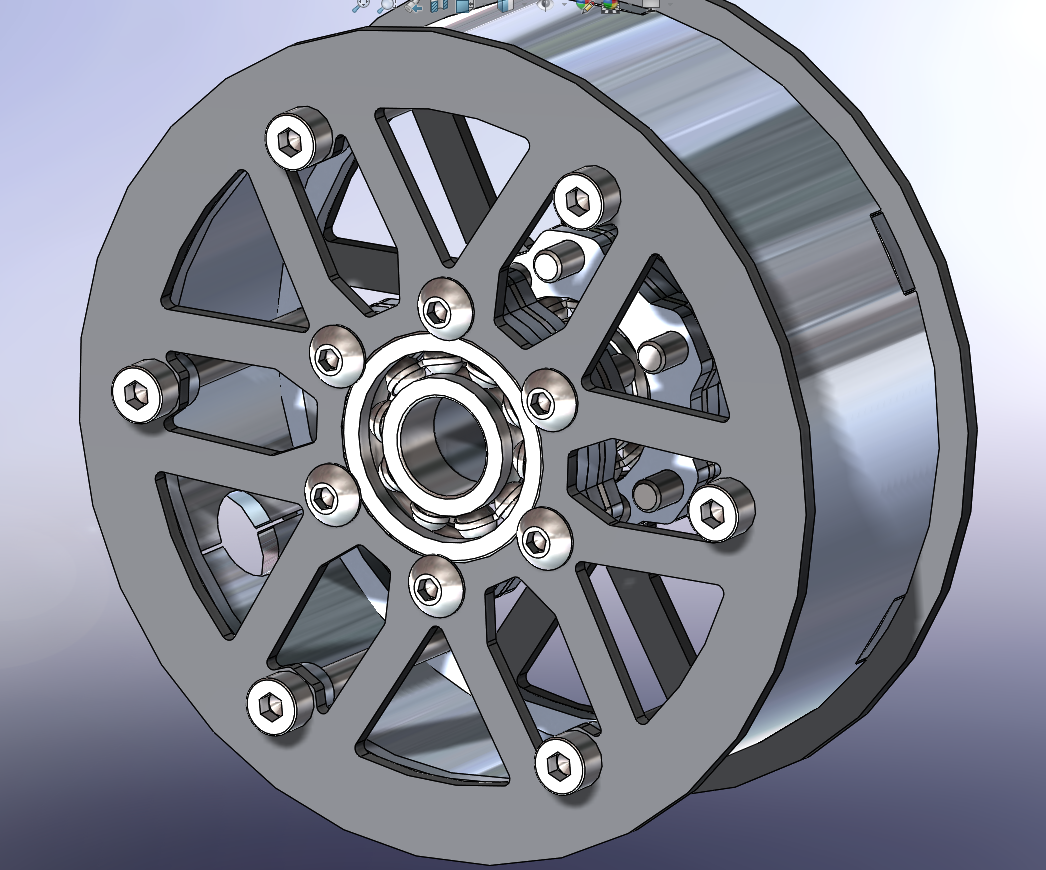

I’ve drawn these hubs from pictures on the internet, it is thus vaguely accurate. I would like to upload the CAD to some site for sharing but at first I need to know how at least some crucial dimensions. I have a feeling that my drive gear sits too far from the wheel… will figure out how to move it closer a bit. Currently it sits 14mm away.

MBS Rockstar Pro hub

If someone can please assist with these dimensions it would be great.

yes flat.

And :

A 12

B 7 / 7.5

C 26

D 28

E 105

F 8

G 3

H 5

I 37/2

PCD 80

Enjoy

yes flat.

And :

A 12

B 7 / 7.5

C 26

D 28

E 105

F 8

G 3

H 5

I 37/2

PCD 80

Enjoy

Edit : Just note that D should get a specific tolerance I guess …

Beat me to it. And nailed it btw.

Many thanks you guys! Awesome!

Your right about “D”… but that’s MBS’s problem. I need to design according to the outside dimensions. Also tried to see if I can have these hubs (or something similar) locally made for less than the price MBS asks on their website, however that seems impossible.

I need to design according to the outside dimensions. Also tried to see if I can have these hubs (or something similar) locally made for less than the price MBS asks on their website, however that seems impossible.  Got myself a go-no-go guage today to test the clamp’s fitting over the trucks.

Got myself a go-no-go guage today to test the clamp’s fitting over the trucks.

Traveling to work everyday, looking for suitable “tracks” to ride ( yes, our roads are not the best)… I’m seriously considering chain drive. Due to dirt and debris… today it’s raining and lots of mud and puddles everywhere.

Sorry, hope this will be the last one… still a few missing. If there is any other dimensions you think I missed please add them. Oh, yes… what is the width of an assembled hub?

Nice Mat !

Total hub W = 38mm

A = +88mm (88.2 /88.25 /88.3…)

B = 93mm

C = 4mm

D = 4mm (4.2/4.3mm)

thanks for sharing back !

thanks for sharing back !

Thanks.

Ok, I’ll load this up to Thingiverse or some site. Are the hubs bolt together with M4 or M5?

MBS Rockstar Pro hub

Yeah ! Awesome, m4 mate

Busy designing my own wheel, sofar it seems I’ll be able to manufacture a wheel for $16 USD. Pitty bearings are so expensive.

It is basicaly two discs AISI 304, 2mm with lasercut 3mm aluminum “arms” forming the cylinder of the hub.

Sent out drawings today for quotes to manufacture…

Looks great and maybe stronger than the earlier design, kudos

I read here on the forum that some say chain drive has better ground clearance… But according to a roller chain sprocket’s geometery it’s actually worse than ‘n belt drive system for a constand gearing ratio. Say for instance I want a 1:5 drivetrain ratio with an M5 pully system one can easily achieve it with a quite standard and common 66:13T selection. But with a roller chain sprocket the smallest motor sprocket on a 05B chain and bore Ø10 is 9T (one gets smaller but bore becomes a problem and 04B chain seems to ne weak). Now to have a ratio of 1:5 the driven sprocket needs to be 45T this sprocket has a OD of 118mm compared to the pully’s Ø105mm. That is 7mm less ground clearance for the roller chain drive system… Wanted to use chain for its advantages with robustness, but it seems to be more impractical.