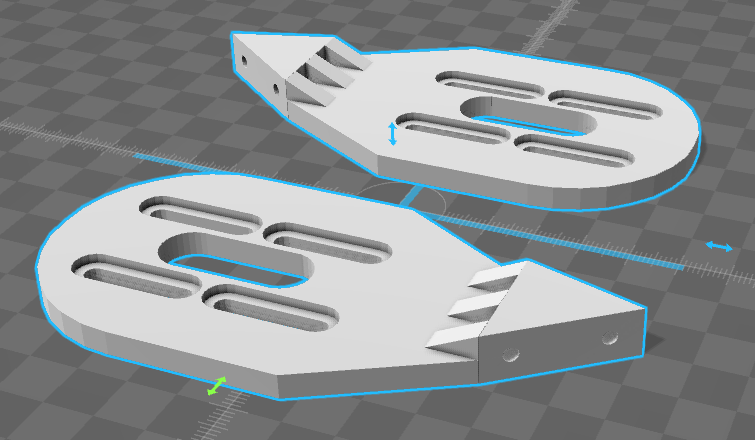

So while i was building my 3rd board i realized that i can´t fit two 5065 in 180mm paris clones.

I just got these from my water cutter. the hanger part is 15mm aircraft grade aluminium and its raw weight is 360grm. while mounts are softer 10mm piece-i-found-on-the-trash aluminium. Mounts weight 130grm each but they will be milled to 5mm except the part where they will be screwed on the hanger. i think mounts will stay on with just two M4 and quality glue. im still not sure do i use press fit on the axles on threads with glue.why not use axle extenders ?

just weld or bolt screw all the mounts on to the extenders . i think i might just do that . have a set of GullWing SideWinders 180mm . wont change or tamper the original trucks .

where can i buy those extenders? i have never even heard of them pretty cool

i thought you knew . just google it "axle extenders’

http://www.sickboards.nl/en/precision-trucks/3137-surf-rodz-20mm-x-10mm-axle-extension.html

https://www.silverfishlongboarding.com/forum/surf-rodz/103519-surf-rodz-extension-axles.html

only found these in web . maybe you’ll find more from your site . i was thinking of buying some few pieces of nuts and screws the same size as the truck’s threads and make myself my OWN axle extenders

because my trial and error styled creating work, i realized that motor holes on these mounts are way too faraway from each other. well back to drawing board.

i used screw axle so i have easy job when pulleys are wornout, old ones out new longer in and ballbeared wheel pulley.

Damn this thing is going to be wide.Looks massiv! Where did you bought these screw in axles? I tried to find them in the past, but the ones I found were ridiculous expensive.

My friend did those M8 in the both ends. took him like 40mins. so far everything is DIY

I see you found an easy fix for your motor hole problem

Orginally i intended to use baseplate i have, but i fucked up as usual.

So now i have to make new baseplate. well at least i can say that i builded my own board.Dude, just cut a little off the triangle at the pivot. Then screw a new pivot in.

I will try that with other hanger that pivot didnt center right. and probably it is best to lower this thing a bit.

thats looking real nice. I thought that the hanger looked a little bit out of proportion in the first few pics. looks a lot nicer now. well done.

how thick are those motor mounts? it looks a little thin. also I notice that you are mounting the motors at the back. any reasons?

Awesome! Drink three!!!

I like to think out of the box, mostly my shit doesnt work  and mounts are about 4mm.Btw this was my first time using the mill or what ever the thing with 8 golden spinning claws that says fuck you to metal is called.

and mounts are about 4mm.Btw this was my first time using the mill or what ever the thing with 8 golden spinning claws that says fuck you to metal is called.

and for the motor direction, this is like lego symmetrical flip it around and it fits

Ah cool. I usually use 6mm brackets and with the nature of skateboarding being a bit rough I have seen some of my 6mm brackets end up bent. 4mm should be ok but maybe go a little thicker next time.