Andy these are Tungsten carbide tip (the darker portion that is mounted in an aluminum body) they will wear extremely slow…how many winter miles are you thinking? These should last many seasons without any noticble wear or performance loss. You should not experience major wear on asphalt.

I am running a 72 tooth hub wheel pulley I purchased from Evolve that fit the all five star (five bolt) MBS hubs. If they can fit the bolt pattern of the hub should work on TB Trucks.

I have about 2km of road till the next park I drive usually. So 4km per trip. For sure it depends on how much snow we will get this year. Would say 50-100km max. Thought about some kind of chains too and already have a design. Think it could be better in deeper or fresh snow, but not sure if diy chains will perform good when driving 30km/h.

I just read your post again and realized you made only a pocket for the studs not a hole and put them through

You made that pocket with inflated wheels. You don´t afraind to burn to deep and hit the inner tube too?

You made that pocket with inflated wheels. You don´t afraind to burn to deep and hit the inner tube too?

No never had problem going through tire as the tip I designed left left 3…4mm of rubber and belt. Have installed over 100 studs no problem, you want to use a larger tire like the MBS T2 with a deep tread to grip snow and studs are for ice. Chains can work as well but I wanted a smoother ride and not thumping of the chains or the worry they would slip in turns…

Kevin

I’ve been trying to do research on those hubs and i love your idea for snow tires.

What i see that at the hubs you linked require a 28mm bearing. On the site, it says they have two bearing sizes, 9.5mm x 28mm and 12mm x 28mm…

Would that option work on a TB truck with a 8mm shaft? My guess is that MBS trucks have a 9.5mm truck?

Thanks!

The axle in my trucks is 12mm…I do think you can get an adapter or sleeve for you 8mm trucks however I have not used one. I do think I have read on the board individuals doing this…

Kevin

thanks for the tip, my guess is that it would look something like this?

So if you wanted to do you setup on like a TB truck, you need to buy the hubs/spikes etc you listed above, then get the link above for the conversions, get a set of 4 12mm x 28mm bearings, and then get the evolve second gen drive gears:

also if i wanted a set of road tires, would these work and would you recommend?

https://www.amazon.com/gp/product/B0021XPF9U/ref=ox_sc_act_title_1?smid=A3HBSOFO6Y4CR3&psc=1

Yes that is the exact pully gear I have used with great success…as they also include extended bolt kit for mounting. You will need to play with your setting on your ecs…,I am running 16x72 with 190kv 6374 duals that provides a good balance between torque and top end. Never have any issue on hills or speed.

Not sure on the tires you listed but you could give it a try…evolve makes a 7” knobby that I think would be better for you. Take a look… https://evolveskateboardsusa.com/products/7-evolve-tire-knobby not sure you will need to confirm they will work with Trampa hubs…

Kevin

A question for you esk8 eskimos. What sensored motors are good for use in snow and getting wet and such? Any recommendations for sealed motors?

Both are nice, eskating.eu 190kV, unikboards 130 and 150kV

https://www.unikboards.com/en/boutique/moteur-skateboard-electrique-6374/

don´t get scarry, i´m not following you

Thats exactly what someone who was following me would say

Any motor would be good if u do some preparations like conformal coating and etc stuff

But where to get good Conformal coating in Europe? And what would need conforming coating? Just the Hall sensor? Or even the windings?

@Kug3lis you skate year round have you had to do any special motor preparations on your all weather builds used in London? I have been running my TB 190kv 6374 (sensored Foc)in all conditions and they get wet and have either been lucky or the probability of an issue is small. Would enclosing or shielding the motors be enough additional protection… Maybe some can research some 3d printable options or @mmaner can design one to go with all the other parts he has on Thingiverse.

The problem with shields is if you make one that keeps the water out, your keeping the heat in. If you make just a bottom half shield to protect from road moisture, rain can still get in the top and vice-versa.

I can model you one, I just don’t think they are very useful for the same reason I don’t use belt covers anymore, creates more problems than it solves. I actually got more rocks lodged in belts with them without.

This is another option http://www.gripstuds.com/ that I have seen. Looks like a sound prduct except the cost is about US dollar per stud. They are far less labor intensive to install but at $40 dollars per tyre is pricey when the method I describe gets the same result at $7 dollars a tire and the tire depth penetration is less.

Kevin

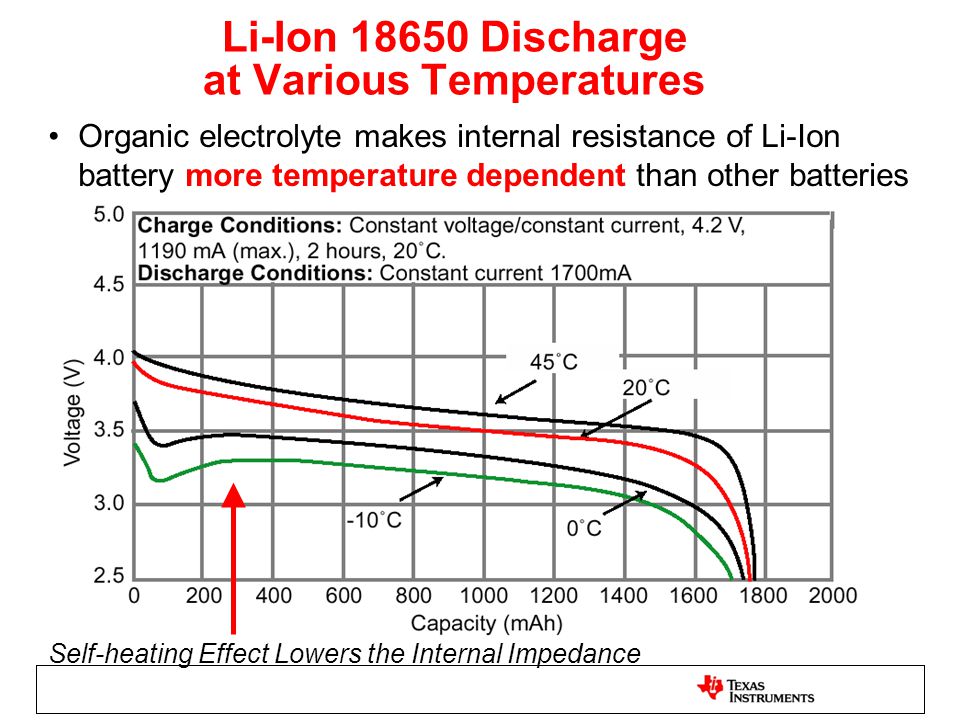

@mmaner agree as I stated I have not ran into any issues and do run in the rain and snow. @mmaner maybe you could share some of the battery power vs temp curves you shared with me for the communities benefit. I always store my boards indoors at room temp and my rides are 5 miles or less typically so I may put a thermal couple in the case at the battery to see how much temp drop happens with low outside temps 32F or 0C.

Its all just stuff I gathered from here, so its not new but if it helps to put it all in one place, Im happy too.

https://www.lithiumpros.com/how-does-cold-weather-affect-lithium-batteries/

https://smartercharger.com/2010/10/how-temperature-can-affect-your-battery/