While building my “Boosted” Clone last year I had the idea to make an Evolve Bamboo board, now that idea is finally going to be put to works!

This project will be a long ongoing project since I’m not getting paid enough anymore to be able to put money aside to this hobby so I most likely will be limited to buying a part a month…

My plan is to build a board that looks exactly like a Bamboo GT But! Way more powerful, better water sealed better range and best of all way more reliable! And as a bonus a lot cheaper!

My goals are to obtain a good 22mph with insane torq! So hills wouldn’t be a problem even though we don’t really have that here in Denmark or at least where I live.

A good minimum of 14 but most likely a good 20-mile range (Should last me a day).

And one thing is not having to care about curbs! I cant drive down curbs without having to check my belt covers or motor mounts to see if I ruined them so this one is kinda important.

The parts I’m aiming for:

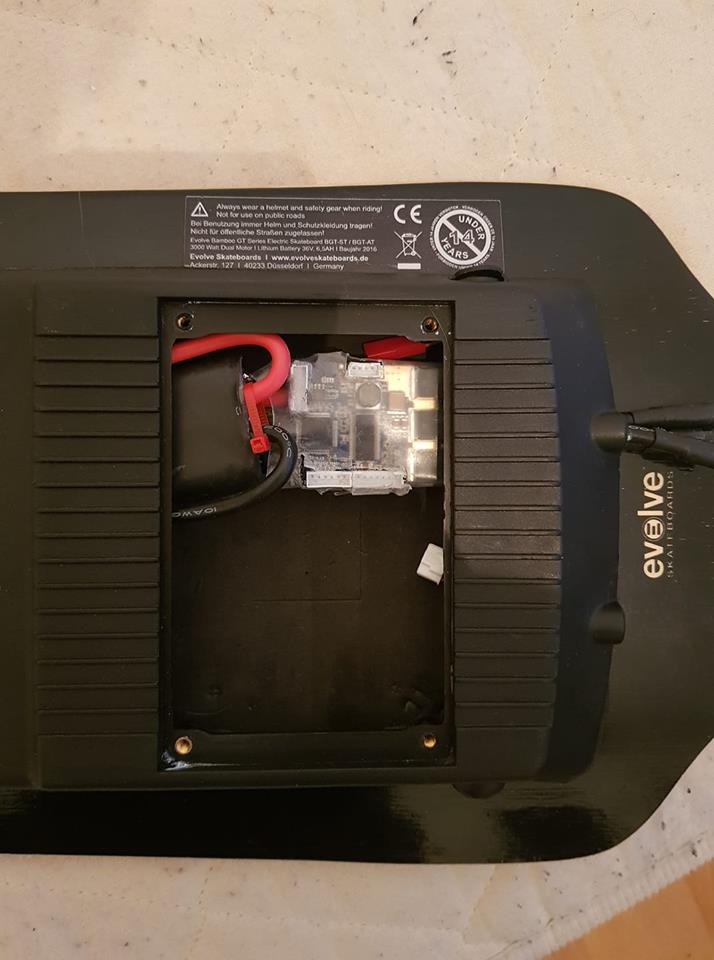

Evolve Bamboo GT Deck: heavy_check_mark: Evolve Bamboo GT Enclosure: heavy_check_mark: Evolve Bamboo GT Front and Rear truck Dual Vesc 4.12 / Dual Focbox: heavy_check_mark: (Currently dual Vesc 4.12 10S3P Battery pack made out of Samsung 30Q Cells Eskating.eu 190KV 6374 3550W Motors: heavy_check_mark: (Got one out of two) MBS 100mm Wheels Black: heavy_check_mark: Pulley + Motor mounts from Evolve or/and Unikboards Antispark Switch with a round button so it fits inside the original Evolve hole Bone red Bearings: heavy_check_mark: Firefly Remote Metr Bluetooth module: heavy_check_mark:

I already know most of the challenges im going into but more will come down the road, the holes for the wires are just big enough for the phase wires so will have to make something for the sensor cable as well, the enclosure is not big enough for anything so a riser out of foam is already made.

I haven’t seen anyone do this before with Evolve Bamboo parts, so interesting to see how it turns out.

Any feedback or help is welcome.

I will try to update everytime i get some major progress done, and explain what ive done so people in the future can look at this post since i know for a fact theres other people planning on doing this as well

I feel, if there solder gets on a grounded pin, the thermal mass gets too large to heat well I think. If you ever get the chance, get a hot air gun to heat the area, and just poke the solder carefully with wick. Hot air seems to be way more reliable at heating stubborn parts like that.

I feel, if there solder gets on a grounded pin, the thermal mass gets too large to heat well I think. If you ever get the chance, get a hot air gun to heat the area, and just poke the solder carefully with wick. Hot air seems to be way more reliable at heating stubborn parts like that.