Helicals need perfect alignment. Axiel load = wasted power and should have a thrust bearing. Precision square cut in oil are stronger, more efficient, more forgiving, and quiet enough. Good luck with Helicals.

same tyres, before his huge markup

Just sayin.

Just sayin.

with double helical you lose the advantage of always having two teeth in contact simultaneously because at a reasonable gear angle you don’t reach the required teeth length as the total gear length is limited.

I am going to order 4 of them.

For German people: keep in mind taxes above a value of 25€ --> ordering 4 individual tires is better than ordering a set of 4 as shipping is free regardless

good point, as long as they don´t just trow them all together and handle it as one order

Then it’s not what I ordered and I’d try to get AliExpress to handle the dispute - should end with me getting my money back. Yay free tires

You could also just order one for each of your imaginary pets that live with you in the same house.

I think i´ll give them a go too for the Hummie deck  So let´s wait for the discount to pop up!

So let´s wait for the discount to pop up!

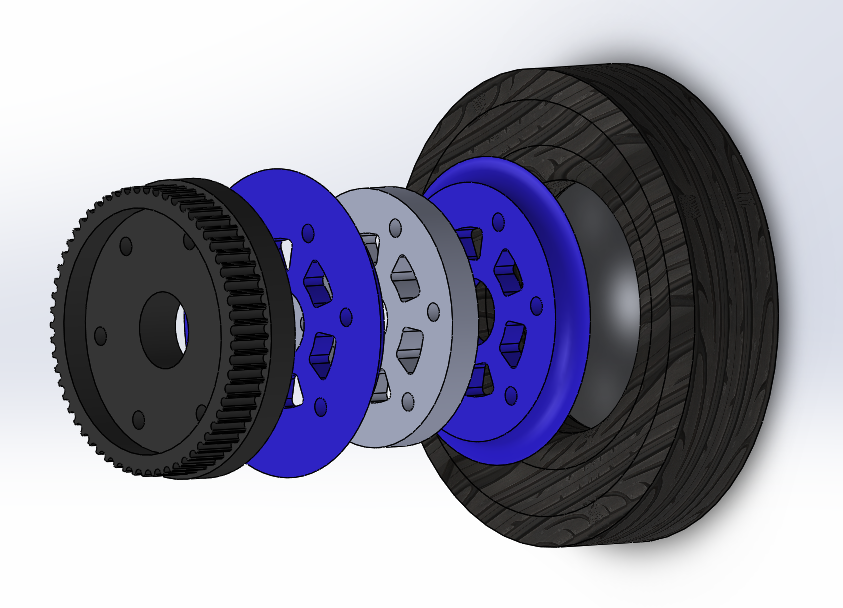

I added a spoke version of the pulley to save some material while 3D printing. I don’t know how well it will hold though. Haha.

Nice sale on AliExpress: the 15% off sale started but you can only buy tires without the hub. Also shipping is not free anymore

Edit: wait a second. The AliExpress cart showed me the wrong product. With the link in the first post you can indeed order with reduced price.

Link in case the other one is not working.

Just ordered! @Maxid thx for reminding me  Let´s wait for them to arrive and have some of you 3D Artists get a good ABS printable file up here to use for a pulley

Let´s wait for them to arrive and have some of you 3D Artists get a good ABS printable file up here to use for a pulley

You should go for gear drive  https://www.electric-skateboard.builders/t/no-words-just-pictures-delete-words-use-pm/2992/6645?u=maxid

https://www.electric-skateboard.builders/t/no-words-just-pictures-delete-words-use-pm/2992/6645?u=maxid

Just ordered one to see how it is, dunno what to expect but they look cool for the price

What’s your initial impression?

Well right now I am just glad the design fits. Will have to test and see if the gears can withstand the forces and actually work. But it’s a fun project and I get better at CAD

Edit: also it’s just so compact

Figured I would give a small update on the one’s I’m working on since I have a similar goal to you (cheap effective pneumatics). I 3D printed all the hubs, and the back right wheel has a slight wobble due to me tightening the plastic a little too much (easy fix by printing another wheel). I’m waiting for my belt to come in to do a real road test with them, however for pushing around they seem to do the job just fine.

Tires I used (They were on sale for $5.31 each last time I checked with that prime shipping): https://www.amazon.com/gp/product/B000N6BR3A/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

Nice. Do you have more pics of how your rim is assembled, your pulley etc. You are welcome to post all the updates here.

Some people generally have a vendetta against cheap stuff but it might just be a little misplaced if the product is actually of good quality. SpaceX has reduced cost of launches by 5-6 times and now it’s gearing to dominate the market. It’s not like the clients are saying that oh it’s cheap it’s bad.

I’ll post the STL files and solidworks models once I’ve tested the design and made sure it’s 100% safe (should be finished up by the end of this week). Until then, I’ll post a picture of the solidworks assembly, and a close up of the wheels. It uses 6x M6 55mm bolts for the wheel+pulley, and 40mm bolts for just the wheel. These wheels fit on standard caliber 2 trucks.

These pictures I’m posting only have the 3 bolts in the wheel (I was just sizing at the time). The ones I actually have on my board right now use all 6 bolts. Bearings were pressed into place using the butt of a metal utility flashlight. One crucial thing about this design is that you don’t overtighten the bolts as it will crush the plastic and cause the wheel to wobble due to unbalance. If 100% effort was brute strength tightening, you only use about 5-10% effort to tighten the nut/bolt against the plastic.

They actually look legit af.

Fair play man, looking forward to seeing where this goes