This one was in the us warehouse. I somehow had it delivered within a week. It’s big for a 3s. So I’m guessing it’ll be sufficient. Just needed to hear a second huzzah. Still have to order the welder HAHA. And batteries…And strips… Fuck this is gonna get expensive again.

Check out the 5Ah version of that battery, the discount is quite a bit steeper. I just purchased it myself for only $38.

Mine arrived yesterday together with some korean newspaper. Aulakiria was so nice and put some nickel strips inside. Will test it later.

I have the 3Ah version which will knock out nickel like a champ but I’d find a 4s for copper. Caveat being if you want to multi-use the lipo in a build and find the 3s versions fit an enclosure choice better…and don’t care about copper welding

Please help me understand what went wrong here:

So today I finally started building my battery. I have the Malectrics spot welder on a 420A car battery. Everything was going smooth as butter. After some tests I decided to go with 30ms pulse time which made the 0.2mm Nickel strip stick to the batteries really well.

When I started welding Nickel on Nickel (the series connections, strip pieces for BMS attachment) it just wouldnt stick as nicely as it did to the battery itself. These didnt tear when I tried to pull them apart but instead the strips seperated pretty neatly. Any ideas for improvements?

Between normal welds, I suddenly had two random welds inbetween that went absolutely bonkers. Loud and bright spark and the one actually BLEW A FREAKIN HOLE THROUGH 2 LAYERS OF NICKEL AND INTO MY CELL!!! - explosing some blue plastic.

Almost lost my cool there for a second, having to tear apart an almost finished pack again in order to replace the cell ![]()

Luckily I bought 2 extra cells for blunders like this.

Can you guys please tell me what went wrong and how I can avoid it in future?

Made a 1s battery from my leftovers. Already have the series connector so now I can add the 1+3s to try some copper welds.

My 3s 6000mah 65c graphene just arrived. muy bueno, big thumbs up. Fully charged, getting perfect welds on .20mm → utility knife blade at 4ms. 7ms too beaucoup, blows holes through.

The 5000mah is much cheaper ($40 vs $60). Was OOS when I ordered, back in stock before my 6ah one got delivered. Grr hobbyking!

kweld was the first one I had my eyes on. I bought the BOSS, but broke down and bought a kweld too. Really robust and powerful. 4 times bigger. Costs more. Gonna be hard to kill, and I like that it measures energy, and is not just a simple timer. The BOSS maxes out at 16ms. kweld at 150 joules stayed on for 80ms. Everything gets hot but the welder. Electrodes, battery wires and connectors all get hot. Fets stay nice and cool.

I have some interesting numbers to share. Both units operate by short circuiting the battery to the weld spots with fets, time controlled. The graphene 3s delivers about 1070a through the kweld. This is dependent on the resistance of the system. If BOSS system has similar resistance, it’s also shooting ~1000A with this battery.

kweld specifies 1500A max.

I got about 1000A with a Tattu 4s 22000mah (22ah!) 25c lipo. The graphene is amazing. kweld maker says the Turnigy Nanotech 3s 65c 5000mah ($50 right now) gives same performance as this Graphene pack. The normal Turnigy 3s 50c packs puffed, but the Nanotech and Graphene took the abuse.

For the graphene 3s, 0.20mm nickel to utility knife blade, kweld at 7 joules was 4ms. 11 joules gave 7ms. This is all around at around 1070A.

I’m getting very strong bonds for 2 layers of .20mm nickel to utility blade at 35 joules, 27ms.

I know this is the BOSS thread, and the BOSS is really good stuff, love it. So tiny and has the high end soldering thing built in. I like the electrode handle.

But I’m sure this info will interest a bunch of people on this thread.

Hi there… Just wanted to ask why my welds are sparking so much… As I tested the nickel strips (Salt and water for 24Hours) they didn’t corrode. So it should be pure nickel! Here the video!

looking at the welds i think you are going way too deep. Lower the time flux. Also is that hilumin? testing it first on a blade will help you find the perfect times.

You are not holding the pen properly. I used to grab it like that when i started lol.

WRONG

GOOD

Put your finger on the blue pvc and give the points more inclination. Make a little pressure to make sure the contact is perfect. Make sure the strips are perfectly clean. If you still have so many sparks that’s not pure or has a very low purity even if not plated. Did you dremel the strips before the corrosion test? it fails if you do not grind it to the soul. The acid must penetrate deeply to provide results.

Yes this is the Boss thread but this is a skateboard community therefore any relevant comment is always welcome. Thanks for your input.

Do you find the results on blades translate very well to 18650 cells?

Of course. The metal (steel) and thickness is similar to the 18650 and you can look to the reverse. That’s a great advantage. Black marks and burnings on the other side are a direct information that you are going too deep. Cutter blades are so far the best test for spot welding i have seen.

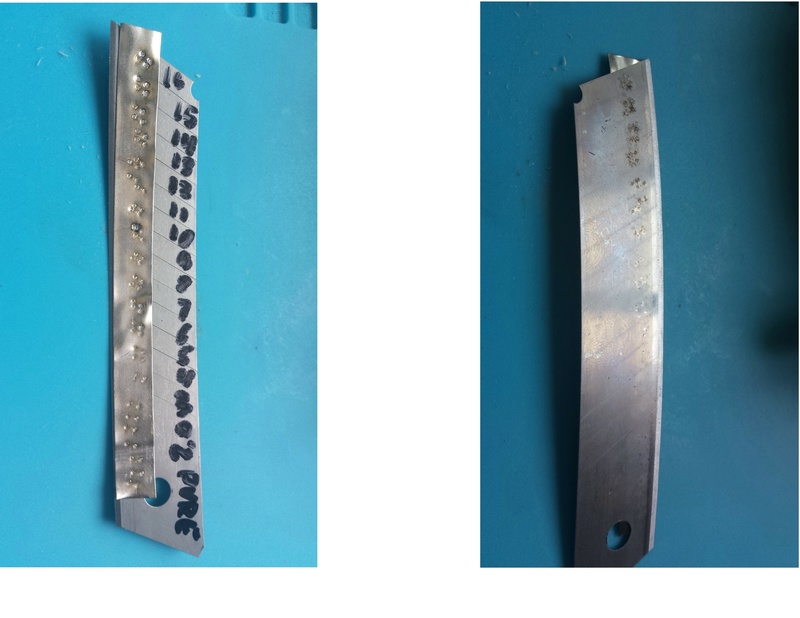

there you go 0.1-0.15 and 0.20 to the max. Looking at the reverse you can figure out when you are going too deep.

One more request, for science.  What’s the thickness of your blades? I’ve been using cheap Harbor Freight utility blades that I have a ton of – not the snap off type. Like this

What’s the thickness of your blades? I’ve been using cheap Harbor Freight utility blades that I have a ton of – not the snap off type. Like this

.57mm thick.

I have snap off blades, Olfa brand, alas black coated, .50mm.

WTF is wrong with me and why didn’t anyone call me out lol. I=V/R that’s directly proportional, not inverse. With constant resistance current goes up as you increase voltage. Sorry guys!

EDIT As for the danger of going 4s, learned from kweld research, there’s a large inductive kickback when you unleash the angry pixies. Voltage spike. So going over maker’s specs may exceed the protections he’s put in. For kweld, in earlier versions he didn’t have enough protection on the voltage converter powering the MCU. Dug up the link: kWeld - "Next level" DIY battery spot welder | Endless Sphere DIY EV Forum

I’ll survive. Lol

Almost 3500 welds strong on this welder now at 4s since. Received it.

hi there!

Thanks for your answer… I did test the nickel strips but only scraping with a knife before putting them into a salty bath. This is what it looked like after 24h. You can see the rust but its more visible on the picture than in RL.

So I took your advice and used a dremel to grind off the potential layers of nickel from the plate and guess what… This is the result after 24h of a salt bath. Only one pure nickel band which I received 2 days ago and didn’t used it for the welds in the video I posted above. I think the sparks come from the steel. Will test it again with pure nickel

Well that’s definitely naughty eBay ‘pure nickel’