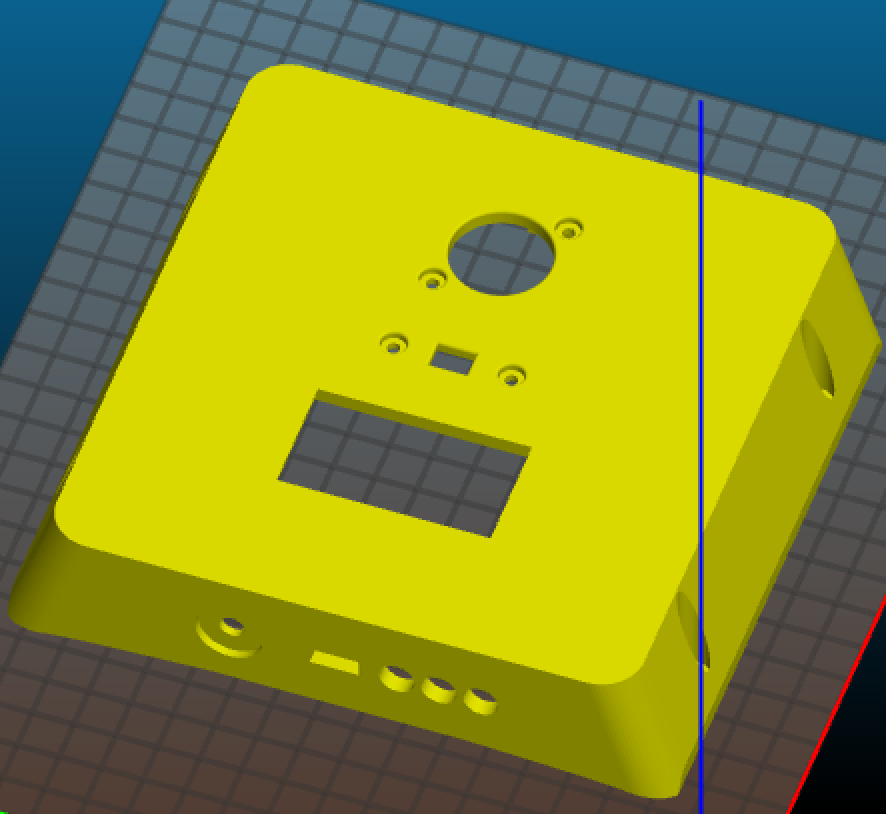

Where can I get that enclosure?

@okp Brother could please PM me STL for that enclosure…it’s amazing. I’d love to print it for my build.

raly nice work!

i recently just tried to design my own covers but they are not half as good as the stuff here. are you willing to share the STL’s?

btw, i used PETG for my covers (motor mount and pulleys as well) and so far it works pretty well.

Really nice designs here! Has anyone tried adding some kind of air scoop to the enclosure to help with cooling? I’m not sure how well it would work, probably depends on your speed, but I imagine it would be pretty simple to add.

Printing my design in 3 parts, part one is now @ 12hours and still 7 to go. Hope the neighbours don’t mind

Like your design @okp, see you did take the concave into account. I hope I can form mine or putt some weather strip underneath. And the screw holes are really nice, takes less space. I did them ‘old school’. And yours can be printed without support, I am now printing with a massive support in the middle, think I’ll print the other ones the other way around, will save allot of time and filament.

yeah, been riding this weekend will look on my computer if I still have the files !

Hey did you every post those on thingaverse or if you have not or don’t intend too. May you share them with me

thanks man!

So my first enclosures were fully 3d printed. they took 10+ hours to print. didn’t look as nice as I wanted, and eventually broke.

A few iterations later, I came up with these! the prints are only used for the endcaps on aluminum sheet bent into boxes. These caps are easy to design, and only take 1-2 hours to print!

embedded the same m3 insert rivets I use for mounting to hold the sheet together! then bend some 1/2 x 1/8 alu flat bar ($3) into mounting brackets!

The down side you need to insulate the inside. the up side they bend/dent but won’t break!

Didn’t like how the other one came out so will try something new.

This is just for the battery, will create a smaller one for the BMS, VESC and receiver.Hi mptrs, I have change you’re design a bit… How do you have add the symbols on the case? And do you have any suggestions?

I used vector images. You can load them into Fusion 360 and do an extrude into the top. Like you did with the letters.

I did a small redesign to be able to print it with the top down. I removed the chamfer and added rounded corners only to the side edges (the ones that go from the bottom all the way up). Cause when I printed it with the top down the concave got ugly (might have been the PLA tho).

Before I printed the box I first tested the edge a few times to get as close to the concave of the board before wasting filament and time.

Good luck printing!

Will do some small edits on this version, like moving the holes for the motor wires down to the board to keep them more low profile, they’re sticking out right now.

just got my 10s3p and looking for some coverage

just got my 10s3p and looking for some coverage